Details

Next-gen Thermal Management

06.05.2020

Ultra-low viscosity Gap Filler Liquids – handling like a potting material while performing like a high class thermally conductive and electrical isolating Gap Filler.

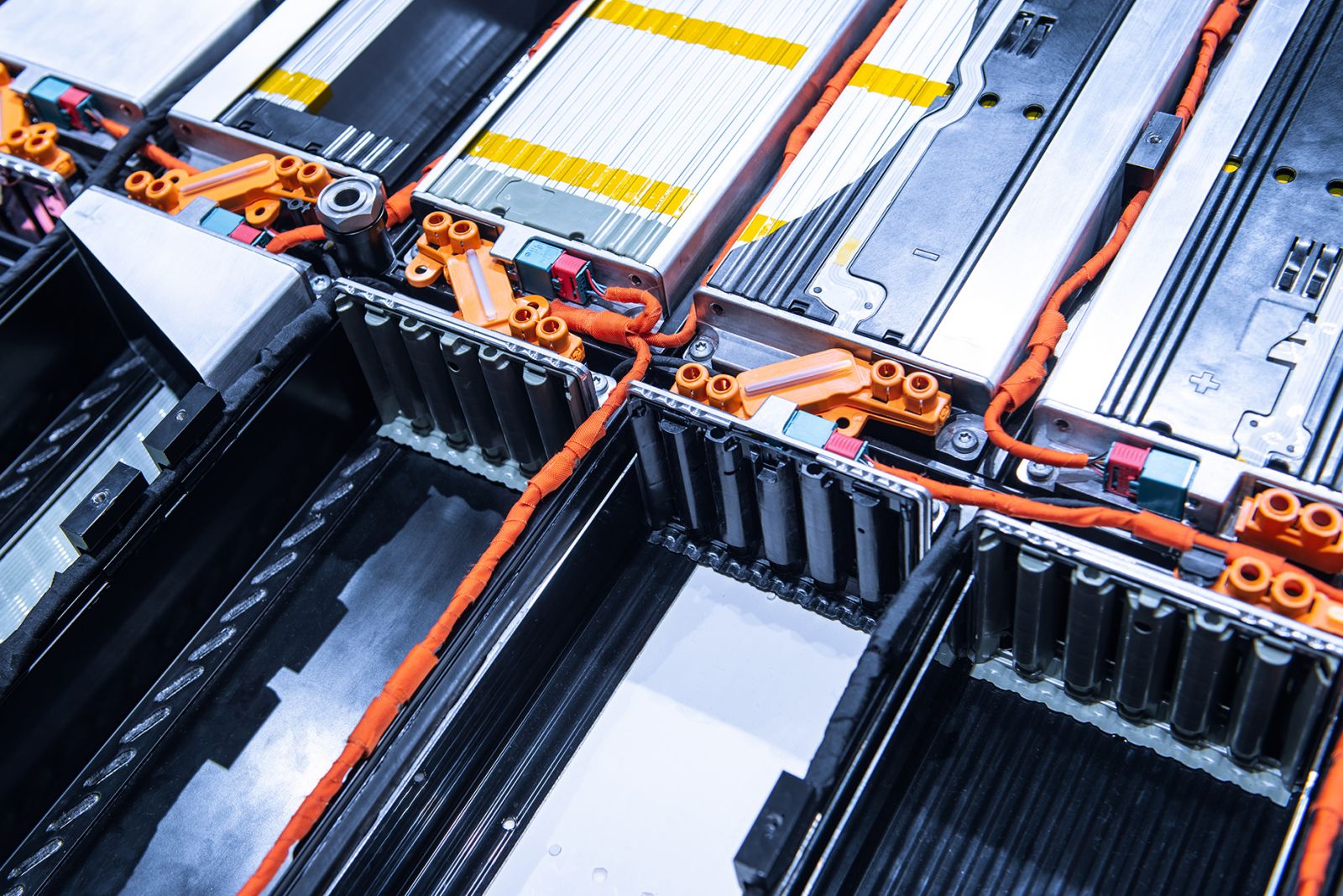

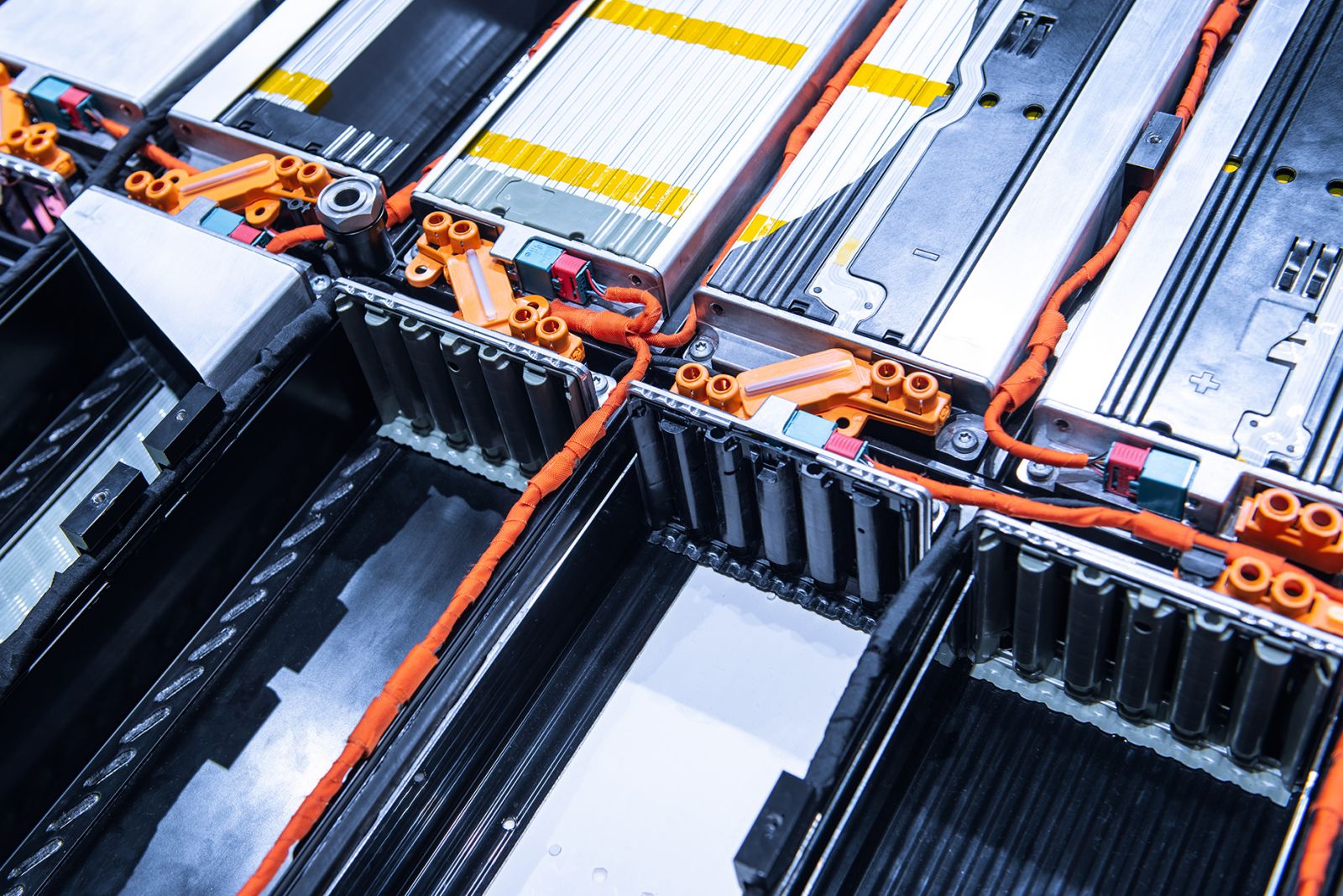

The switch to electric drive systems and the increasing variety of sensors and electronics imply completely new challenges for the automotive sector. Besides the field of electric powertrain, the battery is one of the most critical parts of the EV or PHEV. A perfect temperature control is crucial and therefore, the selection and integration of thermal interface materials is mandatory.

The switch to electric drive systems and the increasing variety of sensors and electronics imply completely new challenges for the automotive sector. Besides the field of electric powertrain, the battery is one of the most critical parts of the EV or PHEV. A perfect temperature control is crucial and therefore, the selection and integration of thermal interface materials is mandatory.

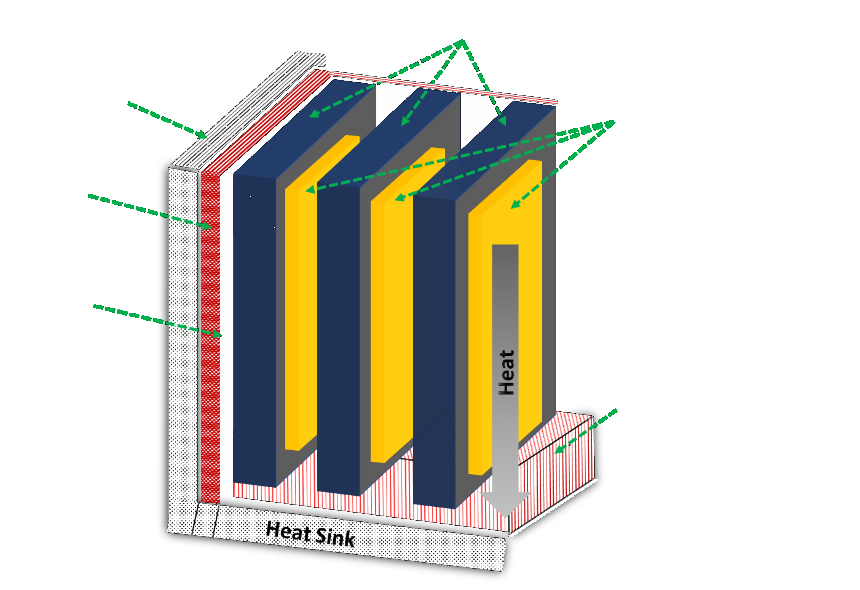

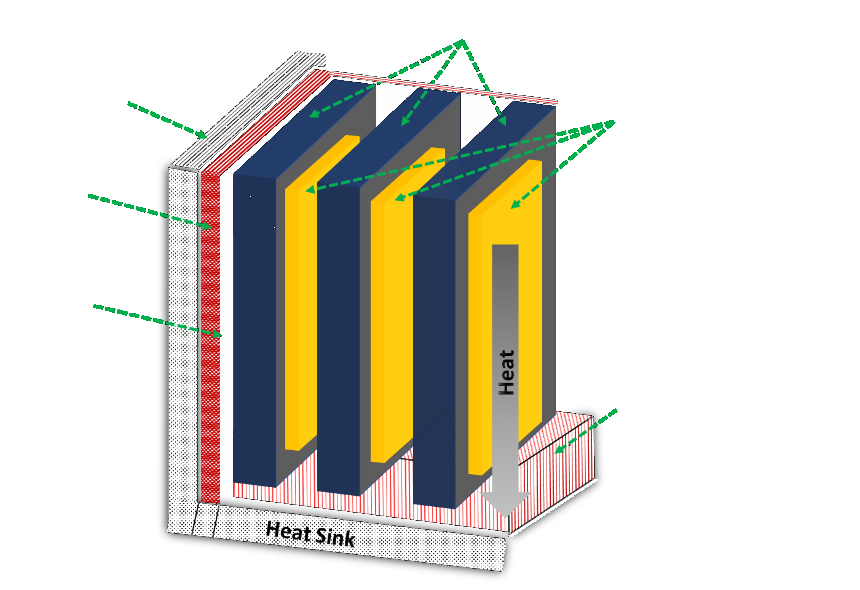

Of course, there are many different types of battery cells, modules, manufacturers and requirements on the market, which vary widely. That in turn leads to a lot of different thermal management solutions that can be applicated. In totally it seems to be the most common solution, to transfer the heat of the cells to the bottom of the module and to connect these cells with a Gap Filler Liquid (GFL), which is compensating any kind of mechanical tolerances. But also a thermal connection to the side of the module can be useful. Due to the size of the battery modules, a very large area and in case of the side connection thin gaps that must be covered.

The switch to electric drive systems and the increasing variety of sensors and electronics imply completely new challenges for the automotive sector. Besides the field of electric powertrain, the battery is one of the most critical parts of the EV or PHEV. A perfect temperature control is crucial and therefore, the selection and integration of thermal interface materials is mandatory.

The switch to electric drive systems and the increasing variety of sensors and electronics imply completely new challenges for the automotive sector. Besides the field of electric powertrain, the battery is one of the most critical parts of the EV or PHEV. A perfect temperature control is crucial and therefore, the selection and integration of thermal interface materials is mandatory.Of course, there are many different types of battery cells, modules, manufacturers and requirements on the market, which vary widely. That in turn leads to a lot of different thermal management solutions that can be applicated. In totally it seems to be the most common solution, to transfer the heat of the cells to the bottom of the module and to connect these cells with a Gap Filler Liquid (GFL), which is compensating any kind of mechanical tolerances. But also a thermal connection to the side of the module can be useful. Due to the size of the battery modules, a very large area and in case of the side connection thin gaps that must be covered.

To fulfil that kind of requirements, always thinking about weight, handling and cycle time, KERFAOL invented an

ultra-low viscosity Gap Filler, the GFL 1800 SL. It is a two-component system with 1,8 W/mK, 15kV/mm and a viscosity of < 5.000 mPas which means about 1/10 of comparable Gap Filler

systems. Therefore, the material is “flowing like water” and has the advantage of self-levelling and filling up every corner, which comes very close to a potting material.

For the thermal connection of the side wall, the dispensing must be started at the bottom to avoid air inclusion. Consequently, a long and very thin dosing needle must be used to fill that kind of small horizontal gap. While it is not possible to fill a gap of e.g. 1 mm with standard Gap Fillers, the GFL 1800 SL has a special particle size, shape and distribution and can be dispensed by small dosing needles that have an inner diameter of only 0,6 mm. It takes only a short time to fill that gap and the curing time of 60 minutes at room temperature can be speeded up with heat. After curing, the GFL 1800 SL, which is based on low volatile silicone, is very stable and at the same time still soft over the whole lifetime, perfect match for compensation of vibrations and thermal expansion of other components. The GFL 1800 SL combines good thermal, electrical and mechanical properties with a new way of processing.

For the thermal connection of the side wall, the dispensing must be started at the bottom to avoid air inclusion. Consequently, a long and very thin dosing needle must be used to fill that kind of small horizontal gap. While it is not possible to fill a gap of e.g. 1 mm with standard Gap Fillers, the GFL 1800 SL has a special particle size, shape and distribution and can be dispensed by small dosing needles that have an inner diameter of only 0,6 mm. It takes only a short time to fill that gap and the curing time of 60 minutes at room temperature can be speeded up with heat. After curing, the GFL 1800 SL, which is based on low volatile silicone, is very stable and at the same time still soft over the whole lifetime, perfect match for compensation of vibrations and thermal expansion of other components. The GFL 1800 SL combines good thermal, electrical and mechanical properties with a new way of processing.

For the thermal connection of the side wall, the dispensing must be started at the bottom to avoid air inclusion. Consequently, a long and very thin dosing needle must be used to fill that kind of small horizontal gap. While it is not possible to fill a gap of e.g. 1 mm with standard Gap Fillers, the GFL 1800 SL has a special particle size, shape and distribution and can be dispensed by small dosing needles that have an inner diameter of only 0,6 mm. It takes only a short time to fill that gap and the curing time of 60 minutes at room temperature can be speeded up with heat. After curing, the GFL 1800 SL, which is based on low volatile silicone, is very stable and at the same time still soft over the whole lifetime, perfect match for compensation of vibrations and thermal expansion of other components. The GFL 1800 SL combines good thermal, electrical and mechanical properties with a new way of processing.

For the thermal connection of the side wall, the dispensing must be started at the bottom to avoid air inclusion. Consequently, a long and very thin dosing needle must be used to fill that kind of small horizontal gap. While it is not possible to fill a gap of e.g. 1 mm with standard Gap Fillers, the GFL 1800 SL has a special particle size, shape and distribution and can be dispensed by small dosing needles that have an inner diameter of only 0,6 mm. It takes only a short time to fill that gap and the curing time of 60 minutes at room temperature can be speeded up with heat. After curing, the GFL 1800 SL, which is based on low volatile silicone, is very stable and at the same time still soft over the whole lifetime, perfect match for compensation of vibrations and thermal expansion of other components. The GFL 1800 SL combines good thermal, electrical and mechanical properties with a new way of processing. Due to that special flow behaviour, also difficult small gaps can be dispensed automatically.

Whether battery, or electric powertrain - The Gap Filler Liquids of KERAFOL are already an approved solution for a wide range of automotive applications.

Wolfgang Höfer (Sales Manager KERAFOL GmbH & Co. KG)

https://content.yudu.com/web/69r/0A18qm2/CIEApr2020/html/index.html?page=28&origin=reader

Whether battery, or electric powertrain - The Gap Filler Liquids of KERAFOL are already an approved solution for a wide range of automotive applications.

Wolfgang Höfer (Sales Manager KERAFOL GmbH & Co. KG)

https://content.yudu.com/web/69r/0A18qm2/CIEApr2020/html/index.html?page=28&origin=reader